Continuous Use Temperature : ~180°C

Thermal Stability : Excellent resistance to prolonged heat exposure.

Tensile Strength : ~70–80 MPa

Flexural Modulus : ~2.4–2.8 GPa

Impact Resistance : High, even at low temperatures.

Excellent resistance to acids, bases, and cleaning agents.

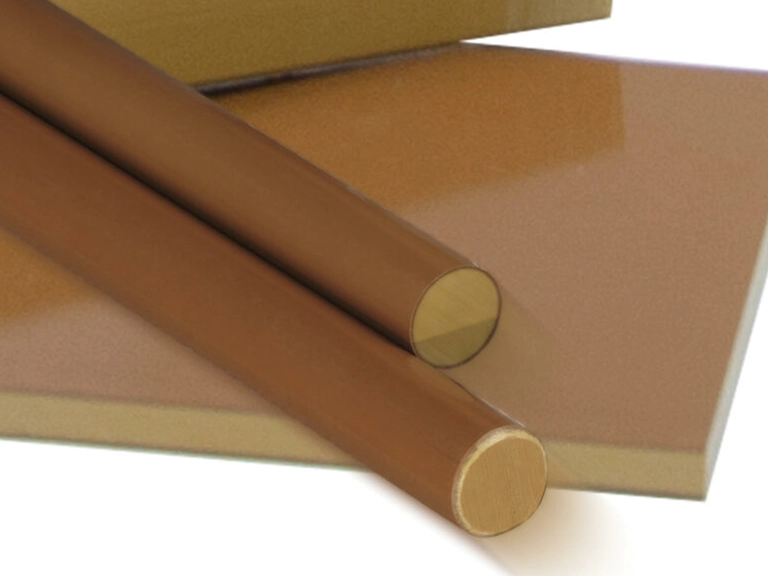

Transparency : Naturally translucent, with opaque grades available.

Get Your Quote or Call: +91 99788 23122

Outstanding performance under steam, gamma, and chemical sterilization.

Resistant to aggressive cleaning agents and disinfectants.

Highest impact strength among sulfone-based polymers.

Retains shape under thermal and mechanical stress.

Inherently flame-retardant without additives.

Exceptional toughness and long service life.

– Dental and medical device housings.

– Reusable surgical instruments and components.

FDA-compliant grades for food contact and sterilizable utensils.

Components for renewable energy systems.

Durable parts in lab equipment requiring sterilization.

Durable and heat-resistant parts for household appliances.

Hot and cold water fittings, pipe fittings, and manifolds.

We are fully equipped with latest manufacturing instruments and well qualified technocrats.

Plot No. 33, Survey No. 238, B/h Vikas Export, Gondal Road, Kotharia, Rajkot-360022

(Gujarat - India)

Copyright @ 2025 Vandit Polycraft PVT. LTD. All Rights Reserved | Website developed By : Impex Infotech